Choosing the right jointer can make a big difference in your woodworking projects. Whether you're a beginner or have some experience, it's all about finding a machine that fits your needs and budget. Here are some key points to consider when picking a jointer.

1. Size and Space: First, think about where you’ll be using the jointer. Do you have a spacious workshop, or are you limited on space? Jointers come in different widths, typically ranging from 6 to 12 inches. If you're working on larger projects, consider a wider model, but if you're tight on space, a smaller jointer can still do the job.

2. Type of Jointers: There are two main types of jointers: benchtop and floor-standing models. Benchtop jointers are portable and great for small projects, making them perfect for hobbyists. Floor-standing models are more robust and ideal for serious woodworkers with heavier workloads. Think about which type suits your style best!

3. Features to Look For: When choosing, consider features like:

Taking your time to research and understand what each model offers will help you make a smart choice. Getting the right jointer can enhance your woodworking experience and lead to fantastic results in your projects!

Understanding Jointer Features and Functions

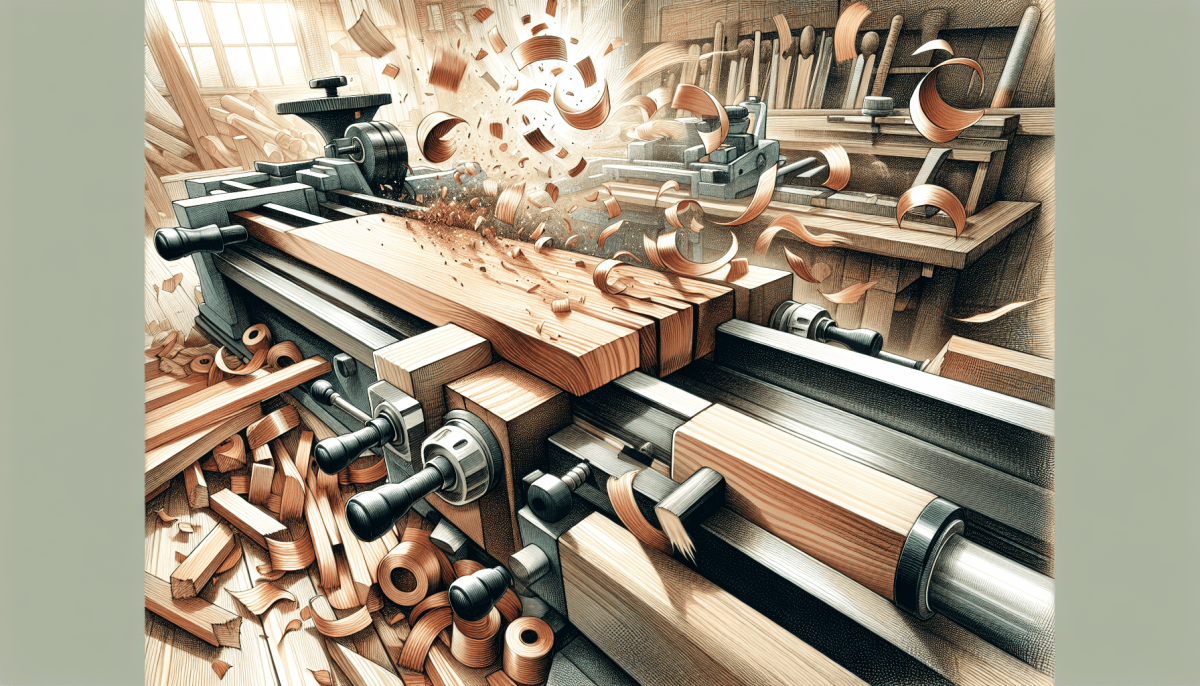

When you're diving into woodworking, understanding jointers can make all the difference in creating smooth, clean edges on your boards. A jointer is a powerful tool that flattens and straightens wood, which is crucial for achieving perfect joints. But what features should you look for? Let’s break it down.

First off, the cutting width matters. Most jointers come in various widths, typically ranging from 6 to 12 inches. If you’re working with larger boards, a wider jointer can save you time and effort. However, if you primarily handle smaller pieces, a 6-inch model might be just right—it's more compact and easier to handle.

Next, consider the blade quality. For a smooth finish, you want a jointer with sharp, durable blades. Some models come with helical or spiral cutter heads, which offer a cleaner cut and longer-lasting performance. Plus, these are often quieter and create less tear-out, which can be a game changer for your projects.

Don’t forget about the table size and stability. A larger table gives you more room to work, helping keep your boards steady as you make passes. Look for a jointer with an adjustable and flat table surface—this will help you achieve that precision you need when squaring your edges.

Finally, features like a dust collection system can save you from a messy workshop. Having a jointer that connects easily to your dust collector means you can keep your workspace clean and focus on your crafting. So, as you explore jointers, keep these features in mind to find the perfect match for your woodworking needs!

Tips for Using Your Jointer Effectively

Using your jointer the right way can make a big difference in your woodworking projects. Here are some tips to help you get the most out of your tool:

Lastly, always keep your hands clear of the blades and use push blocks when needed. Safety first! With these tips in mind, you're on your way to creating perfect joints every time.

Maintenance for Longevity and Performance

Taking care of your woodworking jointer is key to keeping it running smoothly and making sure your projects come out just right. Regular maintenance doesn’t take a lot of time and can really extend the life of your machine. Here are some simple steps to keep your jointer in top shape.

Another important aspect is to make sure your jointer is properly aligned. Regularly check the infeed and outfeed tables to ensure they’re level and aligned with each other. You want your wood to pass through easily without catching or causing uneven cuts.

Lastly, store your jointer in a dry place. Moisture can cause rust and degrade the components over time. If you can, invest in a cover to keep it protected from dust and debris when it’s not in use. Taking these small steps can go a long way in ensuring years of great performance from your jointer.